In recent weeks we’ve been approached by a number of specifiers who tell us that their zinc cladding supplier has insisted that they must have a protective back coating on their zinc cladding.

They have asked us – is this necessary? Our answer is no.

Two of our partner zinc manufacturers produce a zinc product with a protective back coating. These are NedZink NOVA Pro-tec, and elZinc Protect Plus. These products are used in warm roof construction, where the material is applied directly on to a panel without ventilation space. It is particularly useful when you are very limited for depth in the buildup, but it is only suitable for roofs.

All cladding on the other hand, should be vented – that is, it should have a ventilation space behind the material. Without a ventilation space, temperature changes in the zinc can produce condensation behind the cladding that cannot escape, producing a corrosion risk. With correct material specification and construction methods this risk can be eliminated. Both of our manufacturers tell us that in the circumstances of correct specification and installation, a protective back coating is not necessary on zinc cladding.

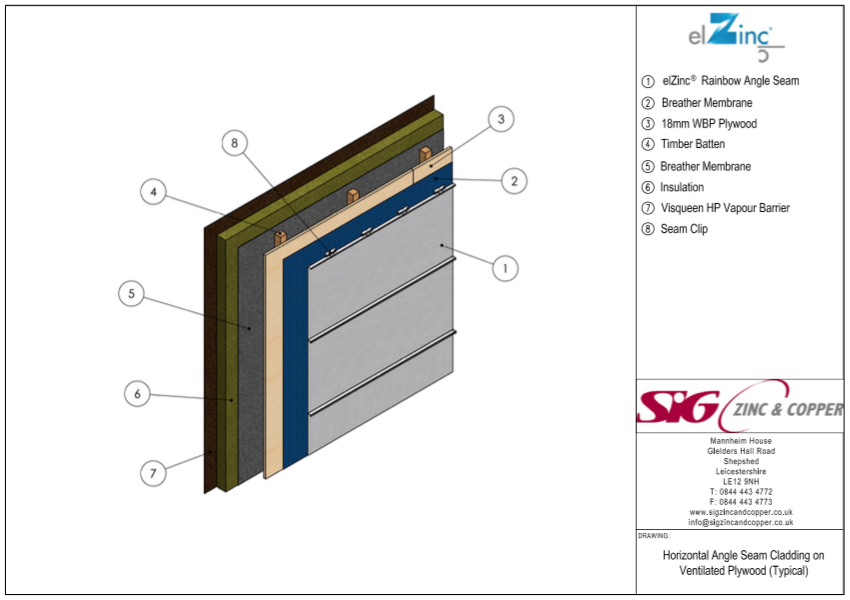

Here’s a typical detail showing elZinc standing seam zinc cladding (without a back coating) installed on a ventilated plywood substrate.

3D Horizontal Angle Seam Cladding on Ventilated Plywood elZinc

![]() Download this typical detail as a pdf

Download this typical detail as a pdf

If your current supplier of zinc for cladding purposes is insisting you specify a protective back coating in addition to the zinc itself, don’t assume you have to find additional budget to pay for it. Good design removes the need for it. Get your cladding designed well and the coating won’t be necessary.

More information

- Get in touch if you’d like advice about your roofing or cladding project.

- Find out more about NedZink NOVA Pro-tec

- Find out more about elZinc and its lovely colours.

About the author – SIG Zinc and Copper Team

We are the team at SIG Zinc & Copper. We design and supply zinc, copper, aluminium and stainless steel roofing and cladding products all over the UK. We also publish blog posts! We're part of SIG Roofing. With over 120 branches nationwide, SIG Roofing is the largest supplier of roofing materials in the UK, providing our customers with impartial advice on the right roofing solution for their projects.

Recent Comments